Wood boiler CTM ECOWOOD +

Price not available, contact us for a personalized quote and to find out delivery times.

To receive a personalized quote, just send an email to fraimsrl@yahoo.it or chat with us!

Advantages of the boiler:

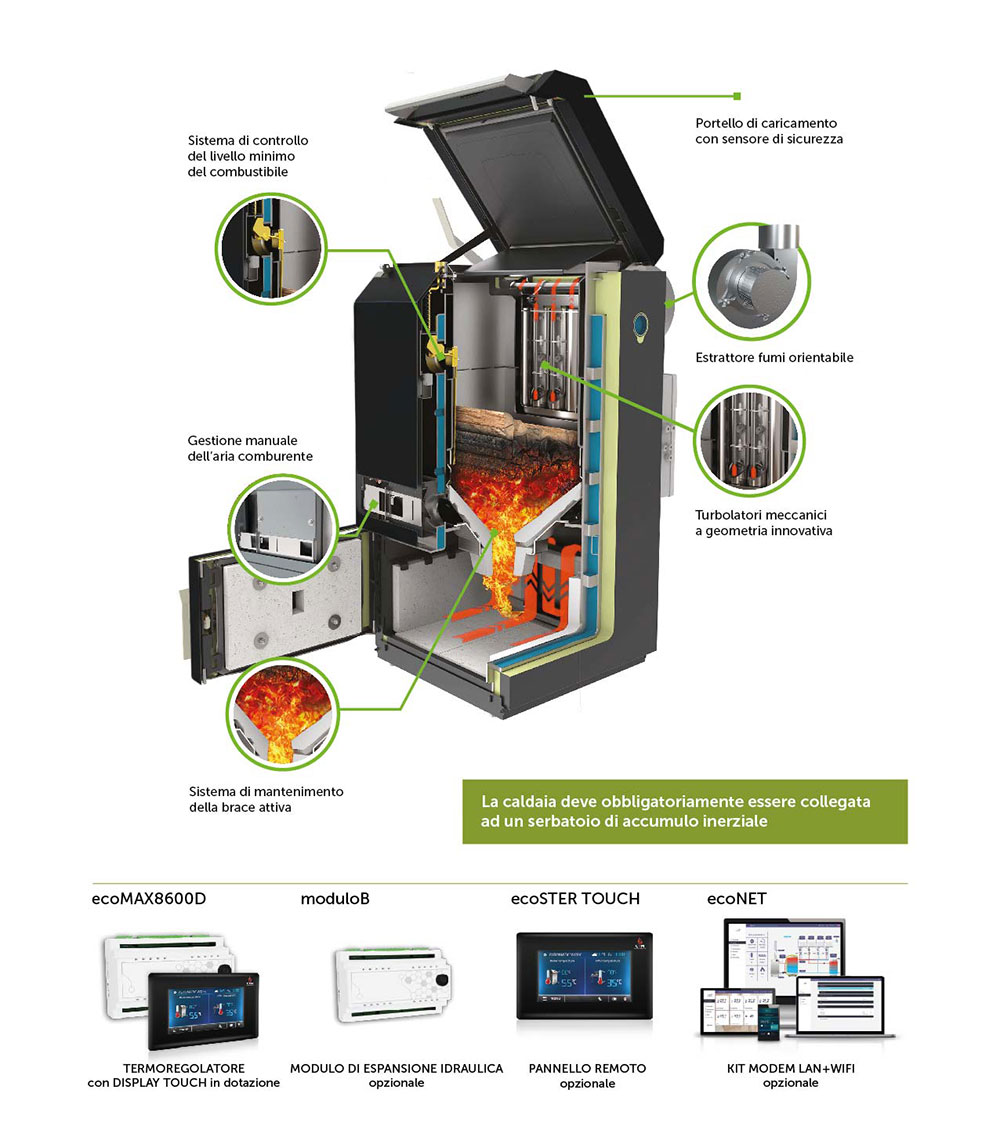

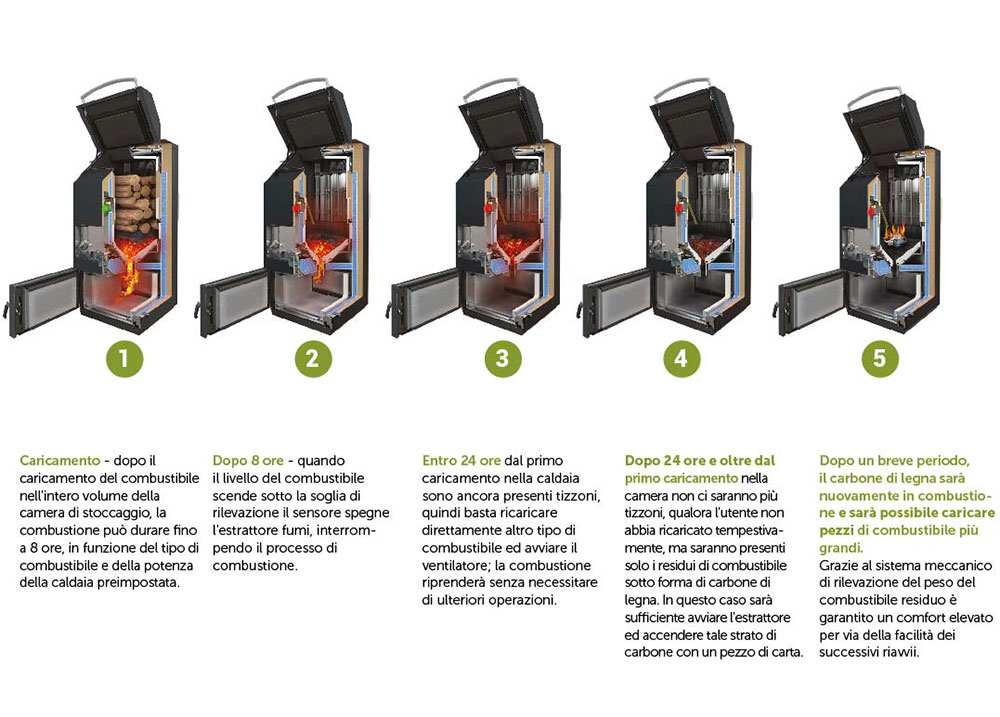

- Automatic ember maintenance system: the reduction of the weight of the fuel beyond a certain limit, due to the progressive consumption, causes the fume extractor to switch off, maintaining a layer of embers in the combustion chamber for a few hours. In this way, the system exponentially reduces the number of cold starts of the boiler during a season. A rapid restart of combustion, even with simple paper, is quick and easy.

- Integrated anti-condensation system: equipped with protection against corrosion generated by the low temperature return fluid, it does not require the installation of further external equipment. An integrated thermostat with pre-set temperature at 60°C and a mixing of the fluid in the boiler body guarantee the effectiveness of the anti-condensation system. A hydraulic connection with natural circulation towards the accumulation tank is possible, without the aid of circulators. 5-year guarantee on the boiler body.

- Dry combustion chamber: the walls of the combustion chamber are insulated, not in direct contact with the fluid, thus reaching a very high temperature and preventing the formation of creosote. The average duration of boilers made with this innovative structure is considerably longer than that of common gasification boilers. The boiler also makes it possible to burn a fuel with a higher humidity rate, without appreciably reducing its duration over time.

- Combustion air inlet on three levels: the supply of combustion air conveyed through three independent channels – pre-drying air, primary air, secondary air – guarantees complete and efficient combustion and very low emissions into the atmosphere, allowing the use of various sizes and types of fuel.

- Ergonomic loading door: for convenient and easy loading of wood and fractionated fuel (wood chips, sawdust, etc.) throughout the combustion chamber compartment.

- Massive loading chamber: burning can last up to 8 hours. In combination with the ember maintenance system, the boiler can operate without shutting down for 24 hours before needing to be reloaded.

- Installation versatility: right/left version of the flap, turbulator levers and connection pieces, fume extractor swivel connection .

- High technology control unit and sophisticated management program: they allow you to directly set the desired combustion power as a percentage and to regulate the boiler, in continuous operation, from 50% to 130% of the nominal power. Setting the power to 50% guarantees a long duration of combustion inside the boiler, with an efficiency comparable to that of the nominal power. This solution allows the boiler to work at reduced power and to install a buffer tank with a smaller capacity.

- Operation with climatic regulation and many expansion possibilities through additional mixing circuits, boiler remote panel with room thermostat function, remote management via internet and via App for Smartphones and Tablets.

| TECHNICAL DATA | Unit of measure. | ECOWOOD PLUS 15 | ECOWOOD PLUS 20 | ECOWOOD PLUS 25 | ECOWOOD PLUS 31 |

|---|---|---|---|---|---|

| Construction standard | - | EN 303-5/2012 | EN 303-5/2012 | EN 303-5/2012 | EN 303-5/2012 |

| Boiler class | - | 5 | 5 | 5 | 5 |

| Energy class EU Reg. 2015/1187 | - | A+ | A+ | A+ | A+ |

| Ecodesign EU Reg. 2015/1185 | - | YES | YES | YES | YES |

| Environmental classification DM 186/2017 | - | ★★★★ | ★★★★ | ★★★★ | ★★★★ |

| Fuel | - | Wood | Wood | Wood | Wood |

| Nominal power | kW | 15.5 | 20 | 25 | 31 |

| Scalable power | kW | 7-20 | 10-25 | 12-32 | 15-40 |

| Maximum heatable surface * | sqm | 170 | 210 | 310 | 390 |

* Sampled at a temperature between 20 and 50 degrees centigrade, referred to dry gas, and at a volumetric concentration of residual 02 equal to 13%.

** The data are to be considered indicative, calculated on an energy requirement of 80W/sqm; variations, even significant ones, can be found in the presence of different energy needs, due to the specific technical-constructive characteristics of the building envelope and of the winter air conditioning system.

Contact us for a personalized quote!